UT Dallas To Lead $30 Million Battery Technology Initiative

By: Kim Horner | Sept. 18, 2023

As announced by the Department of Defense on Sept. 18, The University of Texas at Dallas will receive $30 million over three years from the DOD to develop and commercialize new battery technologies and manufacturing processes, enhance the domestic availability of critical raw materials, and train high-quality workers for jobs in an expanding battery energy storage workforce.

The award, which creates a prototype Energy Storage Systems Campus, is the largest allocation from a federal agency that the University has received to date. The project will leverage and stimulate over $200 million in private capital.

Dr. Kyeongjae Cho, professor of materials science and engineering in the Erik Jonsson School of Engineering and Computer Science and co-principal investigator, will lead the project as the director of the Batteries and Energy to Advance Commercialization and National Security (BEACONS) center.

Key partners include LEAP Manufacturing, a consortium of energy storage companies; AUI (Associated Universities Inc.); the University of California, Berkeley; and the University of Chicago. The agreement provides funding from the DOD’s Manufacturing Capability Expansion and Investment Prioritization Directorate.

“This initiative is a tremendous opportunity to showcase UTD’s mission of research, service and teaching in the context of accelerating workforce development and next-generation solutions that are critical to our nation’s economy and defense readiness,” said Dr. Richard C. Benson, UT Dallas president and the Eugene McDermott Distinguished University Chair of Leadership. “The expertise of our faculty researchers, the excellence of our academic programs in engineering and science, and our demonstrated ability to leverage partnerships with industry put UTD in a unique position to lead this national effort to drive innovation in battery technology and manufacturing.”

The BEACONS center will focus on four main goals:

- Optimizing existing battery systems, including integrating robotics and automation into manufacturing.

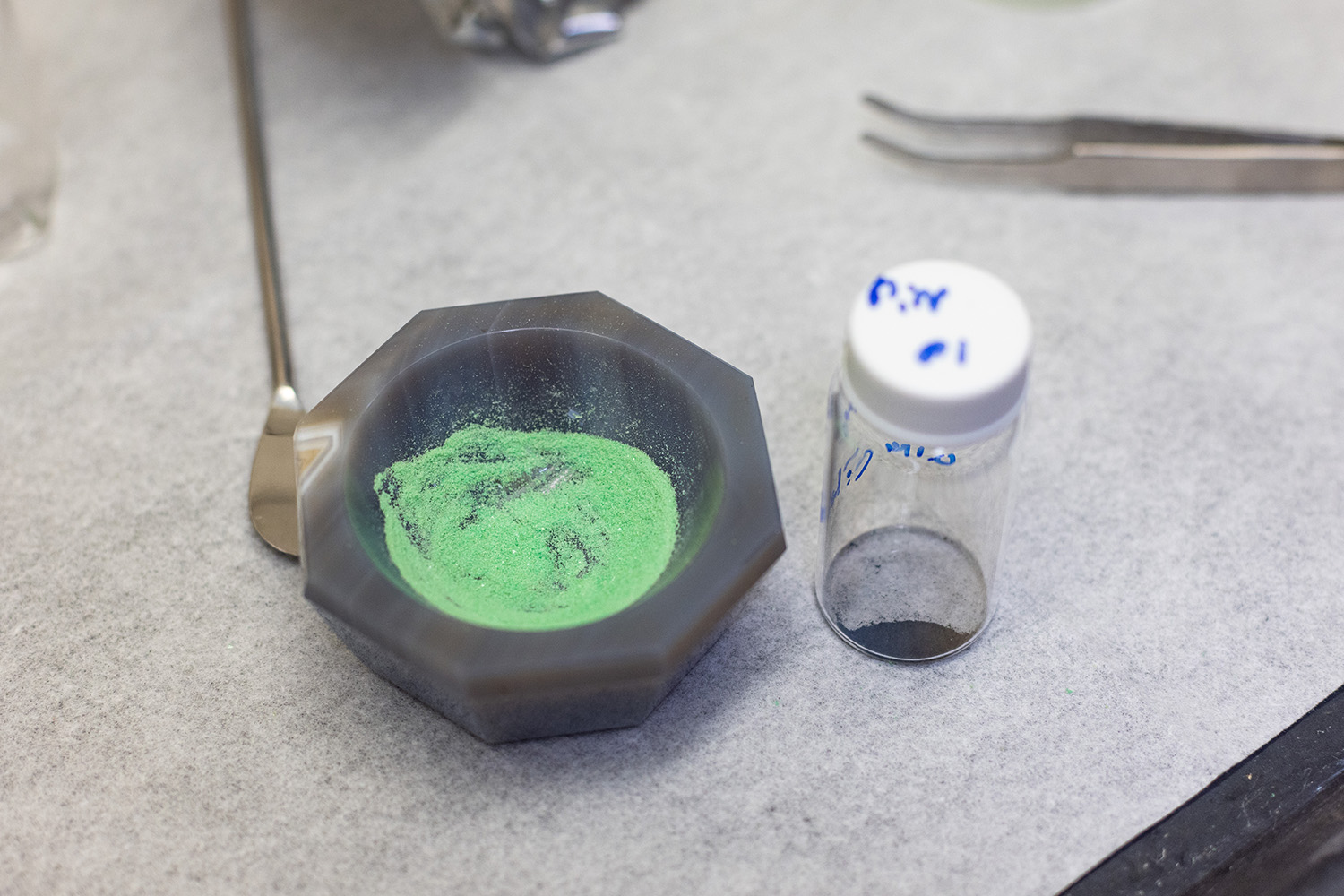

- Fostering the development of new battery chemistries that reduce the use of scarce raw materials.

- Identifying and tracking supply chain challenges for critical minerals, such as lithium, needed in energy storage systems.

- Developing the workforce needed for energy storage system development and manufacturing.

In addition, the initiative will provide access to facilities to help entrepreneurs design, develop and demonstrate novel energy storage systems.

“This initiative is a tremendous opportunity to showcase UTD’s mission of research, service and teaching in the context of accelerating workforce development and next-generation solutions that are critical to our nation’s economy and defense readiness.”

UT Dallas President Richard C. Benson

Response to National Priorities

The National Blueprint for Lithium Batteries 2021-2030, published in 2021 by the Federal Consortium for Advanced Batteries, outlines several goals, including maintaining and advancing U.S. battery technology leadership by strongly supporting scientific research; science, technology, engineering and math education; and workforce development.

The agreement with the DOD is an outcome of more than a year of concerted efforts by UTD leaders and LEAP Manufacturing co-directors Dr. Thomas Campbell and John Stibal to respond to the federal agency’s request for proposals.

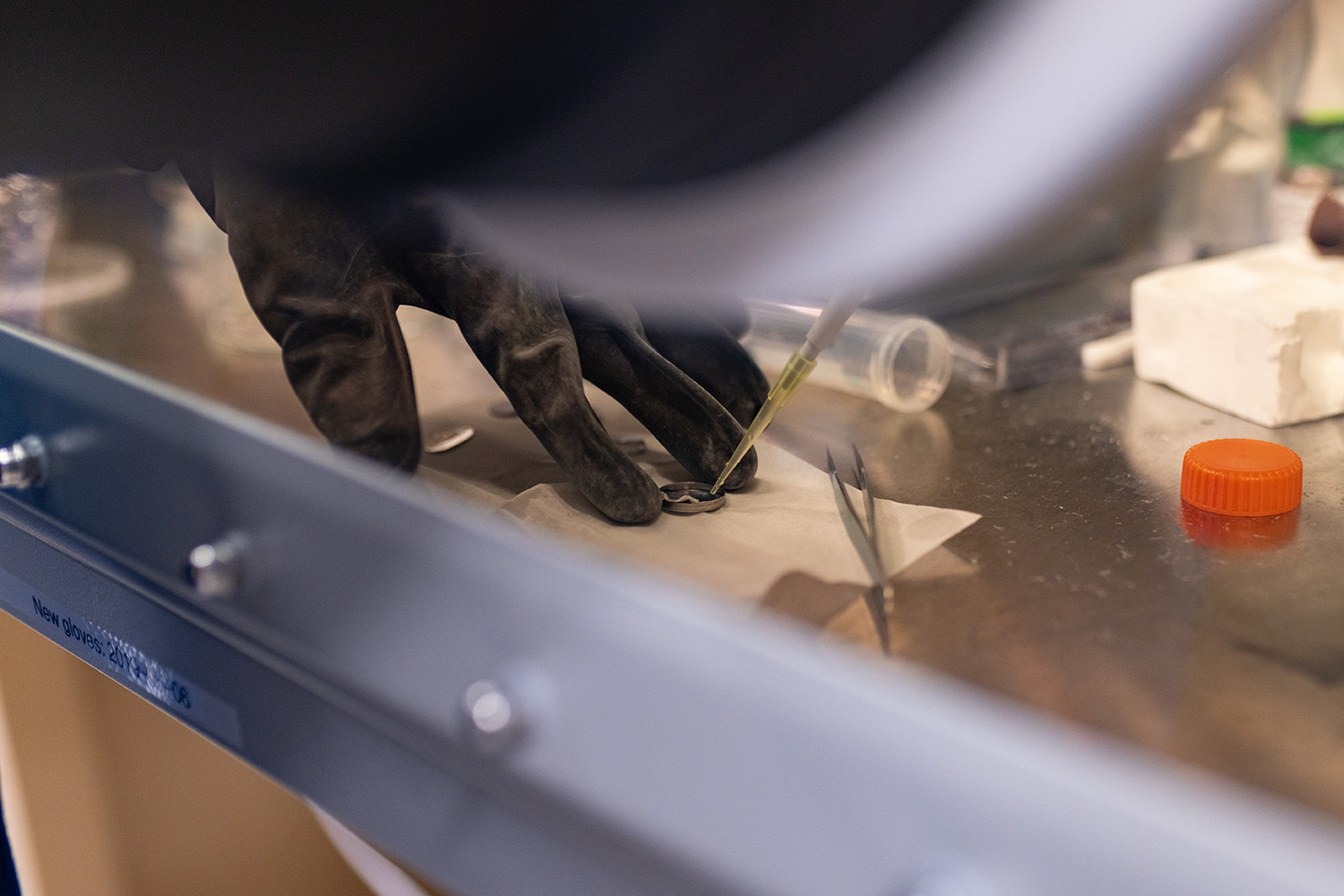

BEACONS will include multiple UTD researchers in the Jonsson School and the School of Natural Sciences and Mathematics who work on energy storage technology, including experts in computer modeling, artificial intelligence, chemistry, prototyping and commercialization. Their work will center on developing safer, longer-lasting and more efficient next-generation battery technology, including alternatives to traditional lithium-ion cells. Lithium-ion batteries, which power everything from consumer electronics to electric vehicles, have disadvantages: They are sensitive to high temperatures and thermal runaway reactions, which can cause fires; they are difficult to recycle; and they require the expensive mining and processing of rare raw materials, such as lithium, nickel and cobalt.

UTD researchers are investigating current battery system optimization as well as next-generation batteries with alternative materials and designs, such as solid-state batteries, which use solid electrolytes instead of organic liquids or polymers, and aqueous zinc-ion batteries, which are made from raw materials that are more abundant.

New Facility

The UTD-led initiative will include construction of a research facility within a 1,200-acre area of the Richardson Innovation Quarter. The facility will include space for developing and manufacturing next-generation batteries, as well as energy storage solutions specifically tailored to defense applications. For example, defense systems operate at extremely cold or hot temperatures, encounter high shock and vibration, and may be stored for long periods then needed quickly for immediate use. Defense battery systems also are sometimes operated in environments where safety demands exceed current commercial requirements.

While the U.S. has been a leader in battery research and technology development, battery manufacturing and supplies of critical raw materials have traditionally been located outside of the country. The DOD initiative reflects efforts to bring advanced manufacturing and supply chains to the U.S., Cho said.

“We identified a unique area that satisfies the Department of Defense’s needs for battery technology,” he said. “This investment by the DOD will facilitate collaboration with our industry partners to help ensure reliable, domestic manufacture of lithium-ion cells, as well as the battery packs that support defense systems and advanced commercial systems.”

Workforce Development

UTD Team

UT Dallas faculty members involved in the Department of Defense-funded battery research project include:

Dr. Kyeongjae Cho, professor of materials science and engineering and co-principal investigator

Dr. Shuang Cui, assistant professor of mechanical engineering

Dr. Joseph Pancrazio, vice president for research and innovation, professor of bioengineering, and co-principal investigator

Dr. Mihaela Stefan, department head of chemistry and biochemistry, and Eugene McDermott Professor

Dr. Laisuo Su, assistant professor of materials science and engineering

Dr. Cormac Toher, assistant professor of materials science and engineering

Dr. Guoping Xiong, assistant professor of mechanical engineering

Dr. Yue Zhou, assistant professor of mechanical engineering

UTD also will partner with community colleges in North Texas to train future employees with a range of expertise. A 2020 report from the U.S. Department of Energy’s National Renewable Energy Laboratory projects that the battery energy storage industry will need a minimum of 130,000 additional workers in the U.S. by 2030; at least 12,000 of those workers will be needed in Texas. Earlier this year, Tesla broke ground on a Texas lithium refinery to produce the battery metal for electric vehicles.

“Renewable energy is a rapidly expanding area, and Texas is leading the country in the expansion of energy storage capacity,” Cho said. “We need not only PhD-level experts, but also technicians who know how to safely handle batteries.”

The initiative is a prototype for collaboration, said Dr. Joseph Pancrazio, vice president for research and innovation at UT Dallas and co-principal investigator on the project.

“UTD and our partners will ensure that laboratory research and creative ideas from small businesses translate quickly toward commercialization,” Pancrazio said. “As a national resource, the collaborative space we’re creating will streamline the path of innovation in energy storage and battery technology, from prototyping and testing to manufacturing. Coupling technological advancement with workforce development ultimately will catalyze economic growth while bolstering national security.”

Batteries 101

A battery consists of a positive electrode, or cathode; a negative electrode, or anode; and an electrolyte in between. In a standard lithium-ion battery, the cathode oxide is made of lithium, cobalt, nickel and oxygen, while the anode is made of graphite, a type of carbon. When the battery charges, lithium ions — which carry an electric charge — move through the electrolyte to the anode and attach to the carbon. During discharge, the lithium ions move back to the cathode oxide and provide electric energy to run devices.

Lithium-ion batteries are pervasive, powering everything from consumer electronics to electric vehicles. But they have disadvantages, including being sensitive to high temperatures and thermal runaway reactions, which can cause fires; being difficult to recycle; and requiring the expensive mining and processing of raw materials, such as lithium, nickel and cobalt. Researchers at UT Dallas and elsewhere are investigating how to make batteries safer and longer lasting, more environmentally safe, and less reliant on expensive and rare minerals.

Media Contact: Kim Horner, UT Dallas, 972-883-4463, kim.horner@utdallas.edu, or the Office of Media Relations, UT Dallas, (972) 883-2155, newscenter@utdallas.edu.