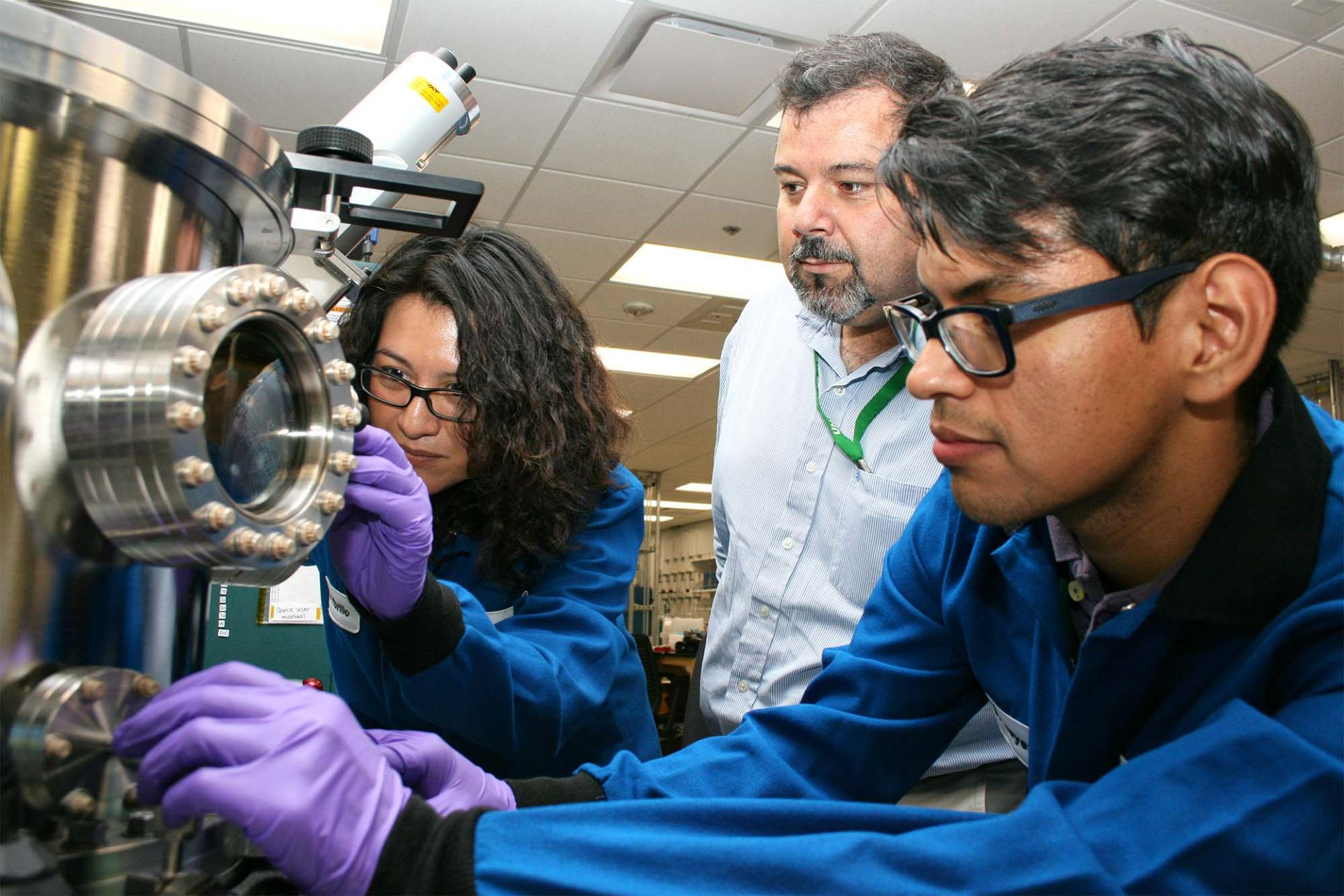

Electronics that will be launched into space or used in military operations need to operate reliably under the most challenging conditions. The University of Texas at Dallas has opened a new research center to advance semiconductor technology and test electronics in this highly specialized field.

The Center for Harsh Environment Semiconductors and Systems (CHESS) addresses a demand for materials and devices that can withstand extreme temperatures, radiation and extreme mechanical conditions. CHESS is the first initiative of UT Dallas’ new North Texas Semiconductor Institute (NTxSI), which aims to accelerate semiconductor innovation, entrepreneurship and workforce development in North Texas.

Dr. Manuel Quevedo-Lopez, director of CHESS, said microelectronic devices capable of operating in harsh environments are vital for national defense in applications such as quantum computing; resilient networks and communication systems; resilient electrical grids; autonomous vehicles; space exploration; and hypersonic weapons, which travel beyond Mach 5, five times faster than the speed of sound (Mach 1).

“Harsh-environment electronics research has become key in industry and national security, and the demand for expertise in this area is growing. CHESS brings together experts who can advance the technology and solve challenges in this highly specialized area,” said Quevedo-Lopez, department head of materials science and engineering and the TI Distinguished University Chair in Nanoelectronics in the Erik Jonsson School of Engineering and Computer Science.

Semiconductor chips — also called semiconductors, microchips or integrated circuits — process, store and receive information. Typically made from thin slices of silicon, one chip can include tens of billions of transistors, or electrical switches, in an area smaller than a fingernail. Extreme heat or radiation can cause a semiconductor to fail.

The effort to develop the NTxSI began more than a year ago to address the need for a coordinated effort in semiconductor research in North Texas and to help alleviate the shortage of skilled employees for the growing semiconductor industry in the region, Quevedo-Lopez said. The new institute positions UTD to contribute to the goals of the recently enacted federal CHIPS and Science Act of 2022. The CHIPS (Creating Helpful Incentives to Produce Semiconductors) Act provides $52.7 billion in incentives over five years for American semiconductor research, development, manufacturing and workforce development.

While the U.S. is a leader in semiconductor design, most manufacturing has shifted out of the country over the past 30 years, leaving the country vulnerable to supply chain disruptions, according to an April 2021 study by the Semiconductor Industry Association. In North Texas, Texas Instruments (TI), Coherent and Globitech Inc. are constructing new semiconductor manufacturing plants in Sherman. The new plants, along with an expanded Richardson TI facility, are expected to boost the region’s position in the industry.

Dr. Joseph Pancrazio, vice president for research and innovation and professor of bioengineering at UT Dallas, said the NTxSI supports the University’s mission to provide innovative research to meet the challenges of a rapidly changing, technology-driven society.

“Harsh-environment electronics research has become key in industry and national security, and the demand for expertise in this area is growing. CHESS brings together experts who can advance the technology and solve challenges in this highly specialized area.”

Dr. Manuel Quevedo-Lopez, director of the Center for Harsh Environment Semiconductors and Systems

“Through the North Texas Semiconductor Institute, the University will play a key role in regional efforts to strengthen U.S. semiconductor manufacturing capability,” Pancrazio said. “The institute builds on UT Dallas’ leadership and expertise in semiconductor innovation by providing support to entrepreneurs, workforce training and specialized research.”

To learn more about how UT Dallas is enhancing lives through transformative research, explore New Dimensions: The Campaign for UT Dallas.

UT Dallas hired two former TI experts to lead the institute. Dr. Ted Moise, the institute’s director, received the Edith and Peter O’Donnell Award for technology innovation from the Texas Academy of Medicine, Engineering, Science & Technology in 2012 for his development of ultra-low-power ferroelectric random-access memory. That major breakthrough provided a new method for storing data on a chip and made it possible for electronics to work faster, store more data and use less battery. Dr. Robert Baumann, who retired from TI in 2018, directs the efforts in radiation effects in materials and devices. The former chief technologist for TI’s high reliability product group, Baumann co-wrote TI’s Radiation Handbook for Electronics. Both Moise and Baumann are IEEE Fellows.

As the local semiconductor manufacturing industry grows, institute officials estimate that the new manufacturing facilities will create over 17,000 semiconductor manufacturing, technology development and management jobs over the next few years. The institute hosted a one-day Workshop for North Texas Semiconductor Workforce Development on Dec. 7 to meet with leaders of local semiconductor companies to discuss workforce needs.

In addition to its focus on workforce development and harsh-environment electronics research, the NTxSI plans to develop a venture startup accelerator and an advanced prototyping facility to help entrepreneurs in the semiconductor industry. These future initiatives will address the high capital costs facing startups and small businesses in the industry and the lack of access to fabrication facilities.